Test Systems

SOLUTIONS FOR YOUR TESTS

Having the know-how to supply “turn-key” solutions such as calorimeters, test rooms and manufacturing testing, we have created custom systems for some of the most important companies in this field.

THE WINNING SYNERGY

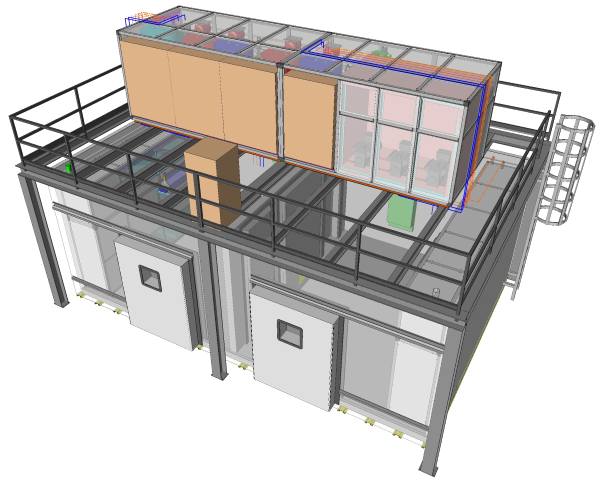

“Turn-key” solutions are assembled in the factory located in Varese, where the pre-testing of the complete system is carried out with the customer. This allows the customer to verify the system, before it is delivered to them, with the enormous advantage of reducing assembly time and the system start up in the final location, achieving full customer satisfaction.

This strong synergy allows us to offer innovative technical solutions that are very attractive in terms of price, with a close integration between the system management logics and the mechanical/hydraulic devices. Other advantages include the test times (operating conditions are achieved very quickly) and reduced operating costs (including the reduced cost of energy consumption and maximum automation of testing).

Our decade-long experience and the know-how acquired through the crafting of complex and cutting-edge solutions for leading companies worldwide has enabled us not only to provide “ready-made” solutions with no unknown technical or design specifics, but also to handle requests for different types of systems.

By choosing the “Project Engineering – Air Control synergy”, the customer has a single point of contact and the advantage of being able to benefit from specialized skills that perfectly complement each other (www.calorimetri.it).

EXAMPLES OF “TURN-KEY” SYSTEMS

- Testing room for heat pumps (water/air or glycol) – EN 14511 and EN 14825 (part loads).

- Testing room for commercial and domestic refrigerators – UNI 23953 (former EN 441).

- Manufacturing testing of air and water condensed chillers – EN 14511 and EN 14825 (part loads).

- Testing rooms for air and water condensed chillers – EN 14511 and EN 14825 (part loads).

- Testing rooms for air-to-air recuperators – EN 308 e EN13141-7.

- Testing rooms for heat pumps for domestic hot water production – EN 16147.

- Testing rooms for domestic electrical storage water heaters production – prEN50440

- Calorimeter for air conditioners (monoblock and split) and chillers – EN 14511 e EN 14825 (part loads).Cooling capacities range: 0.2÷6 kW; 5÷17 kW; 1÷50 kW; 5÷100 kW.

- Calorimeter for fancoil – EN 1397.

- Enthalpic tunnel for air conditioners and fancoils flow and efficiency measurements – AMCA 210-99.

- Tunnel for fan flow measurement from 50 up to 100.000 mc/h – UNI 10531.

50023 – Impruneta – Firenze

Phone: + 39 0552020179 – Fax: +39 0552022474

info@proeng.it